About Global Lift Used Forklifts Bellevue

Global Lift Bellevue - The following forklift classes describe the use and fuel choice of each forklift. Certification is necessary for every class of forklift which the operator would be using.

Class 1

These forklifts are available with either pneumatic tires or cushion tires. Pneumatic tires are recommended in dry conditions for outdoor application. The models with cushion tires are made for indoor surfaces that are smooth. These are electrically powered vehicles that use industrial batteries, which make them desirable within closed locations where the quality of air is an issue. Hoist functions and travel are controlled by transistor motor controllers. These are versatile units usually used everywhere from the loading dock to the storage facility.

Class 2

For the kind of location where narrow aisles must be negotiated, this particular kind of forklift is suitable. They are effective at maximizing the use of storage space. Their unique design makes them perfect where speed is needed and for small spaces.

Class 3

These are hand-controlled and battery-powered models. Using a steering tiller, the operator can control the lift while standing in front of the truck. The tiller has controls mounted on top and is moved laterally to maneuver the vehicle. The units which have smaller capacity utilize industrial batteries.

In the US, 20,000 people are injured each year in accidents related to the use of forklifts. And each year roughly one hundred deaths are attributed to forklift accidents. Fortunately, correct training concerning operation procedures and maintenance can considerably reduce the chance of accidents. The basic safety regulations and suggestions below should be followed whenever utilizing a forklift.

The employer is responsible for making sure that employees are trained to use a forklift and have undergone a correct training program. Training includes a combination of lectures, presentations, practical hands-on training and discussions. Reevaluation should occur every three years. Forklift operators must be up-to-date with current forklift safety rules. Forklift training program content covers general workplace hazards, dangers of forklift operations, workplace surfaces and lighting, and dangers connected to operating the particular forklift which the employee would be using. An employee must be at least eighteen years old to utilize a forklift.

Forklift inspections should be carried out on a daily basis to be able to ensure the proper and safe functioning of the machinery. The inspection includes keeping a checklist of things and reporting any concerns at once.

Having a safe and clean workplace is essential in the safe operation of a forklift. A work site that is safe means establishing "traffic lanes" that are designated for forklift use only. Warning systems such as horns and flashing lights should be in place to be able to indicate when there is a forklift approaching. Forklift docking stations must be kept in good repair and inspected daily.

General safety guidelines for forklift use comprise respecting the load capacity of the forklift and never exceeding the maximum; avoiding known hazards on the ground, such as wet spots or oil spills; making sure that there is enough clearance for the load; lowering or raising the load only while the forklift is stationary; and keeping arms, legs and hands in the vehicle during operation.

Forklift certification really helps to be able to ensure that businesses are in compliance with regulations and legislation. Forklift drivers have to go through certification before being permitted to run machinery. In places where certification is not necessary by law, training is helpful for individuals looking for industrial jobs. People who are certified are normally selected over other applicants because of this particular training. Forklift operators who are certified are often paid better as opposed to those who are not licensed. For companies, having forklift drivers who are properly trained means increased productivity, fewer workplace accidents and fewer product damage during loading or unloading. If companies follow governmental guidelines by providing training to their staff, they can achieve better ratings on their safety inspections, possibly reducing insurance expenses.

It is recommended that individuals receive licensing through a formal forklift training program. Warehouse work might be easier to obtain with a license as certification shows to a boss that the one applying has the skills necessary. A forklift license is recommended due to the advantages to both the business and the employee. A skilled driver saves resources because of less incidents, that means savings on expenses associated with loss of time or hospitalization. A forklift operator who is licensed can be depended upon to work more effectively and efficiently than one who is untrained.

A formal forklift certification training program can differ in length which depends upon the type of forklift utilized in the instruction, class size, and experience and aptitude level of trainees. Certification usually requires the trainee to pass a written test and practical exam before a license can be given. Upon successfully finishing a formal training program, graduates would be qualified to get a job in a variety of businesses.

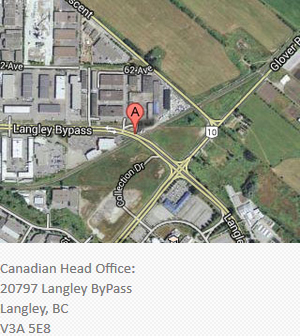

Contact Info

Questions or Comments